Dense Air Injection

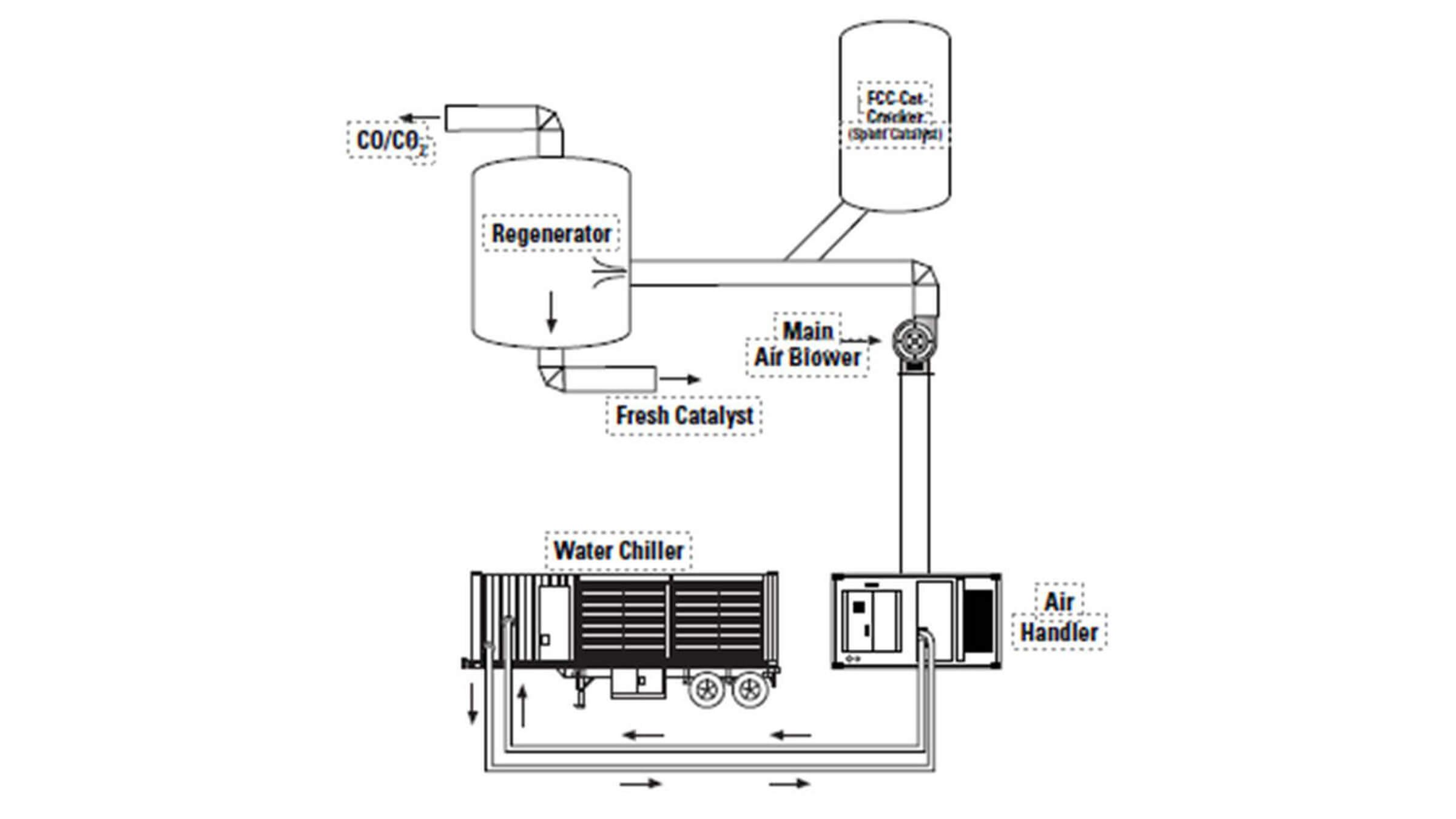

Oxygen and combustion-dependent processes, such as sulfur recovery, chemical reactions, incineration, and furnace operations require oxygen-rich air. During the summer months, the air is less dense, resulting in less oxygen per cubic foot of ambient air. Production rates can be maintained by chilling the air and blowing it into the process. A common use for dense air injection involves the regeneration of catalysts by burning off impurities (such as in the cat cracking process.) A typical installation is shown below.

Rental equipment typically used for dense air injection applications includes the following:

Air conditioners from 60 to 90 tons (multiple units)

Chiller modules with air handlers ranging from 150 to 525 tons

Air Handler Units

Ducting, piping, and fittings

Engineering and supervision services

Installation and maintenance services

On-site operation and training

Typical Customers:

Many production and manufacturing processes depend on an adequate supply of oxygen.

Refineries

Chemical plants

Ammonia and fertilizer manufacturers

Acrylic manufacturers

Companies with large incinerators or other combustion-dependent operations

Discovery Questions:

Are your processes ever “air-limited” during the summer months?

At what ambient temperatures do refrigeration rates become limited?Would increased oxygen levels improve your incineration or furnace processes?

Configuration and Installation Issues:

Piping and/or ducting requirements must be identified. Air intakes for these applications are often in overhead locations. How will ducting be supported?

Be aware of area electrical classifications.