RENTAL HEAT EXCHANGERS

Whatever your project entails, we have a turnkey solution.

HEAT EXCHANGERS

Heat exchangers in an industrial plant setting play a vital role in lowering and raising the temperature between two different media, usually fluids. Several configurations of heat exchangers exist, and we specialize in renting two types to facilities with a planned project or emergency need.

Plate and Frame Heat Exchanger Rentals

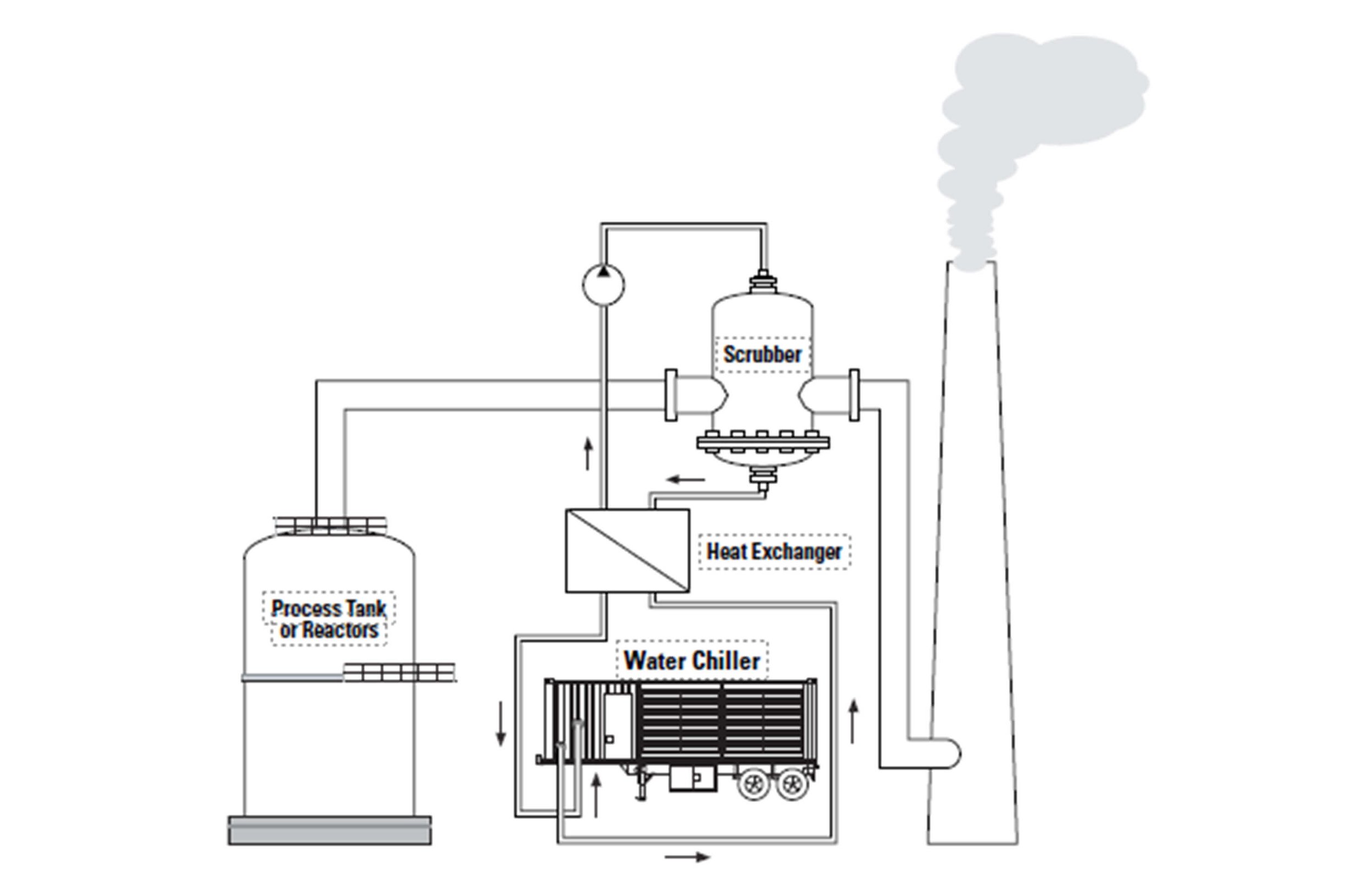

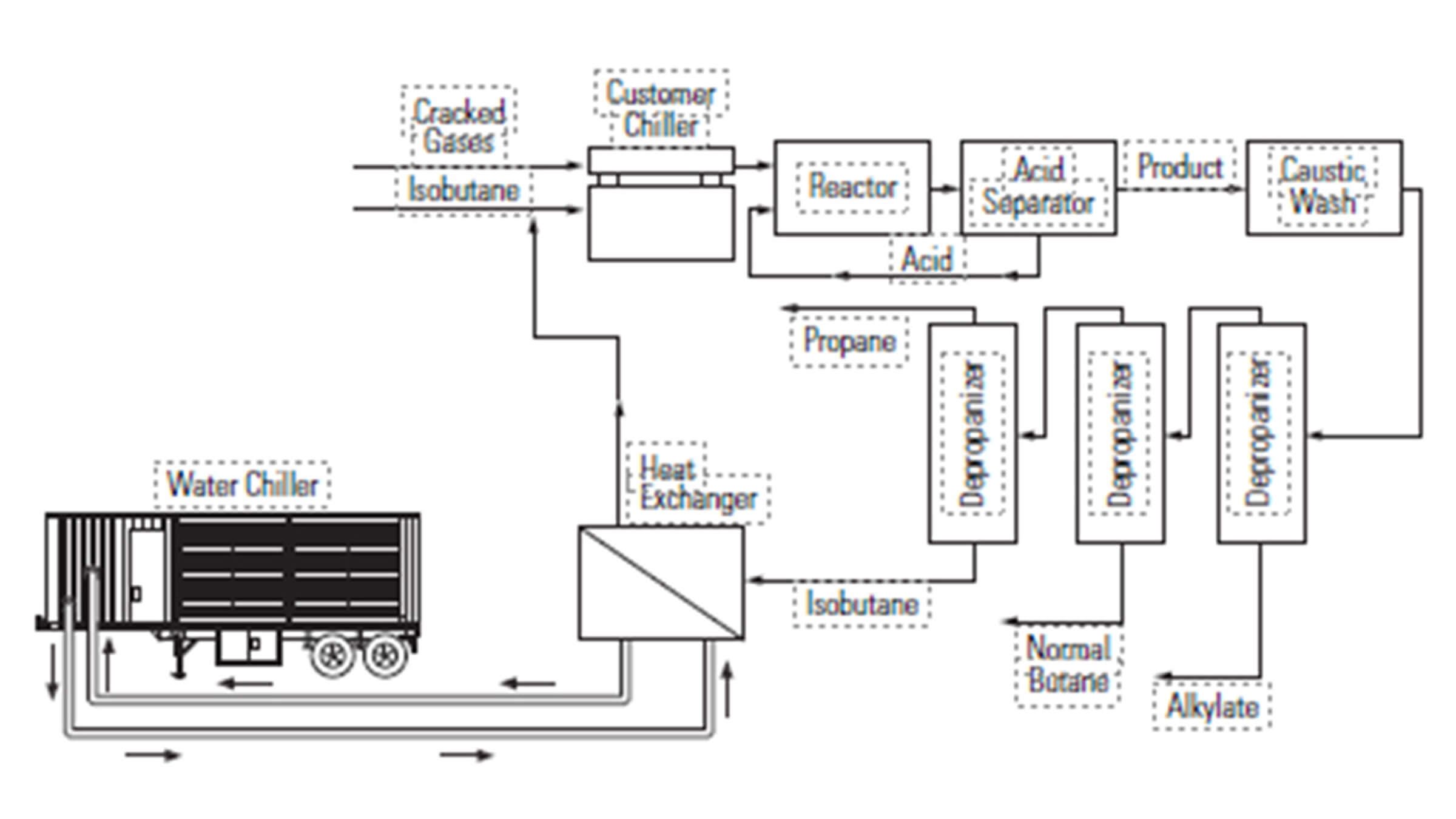

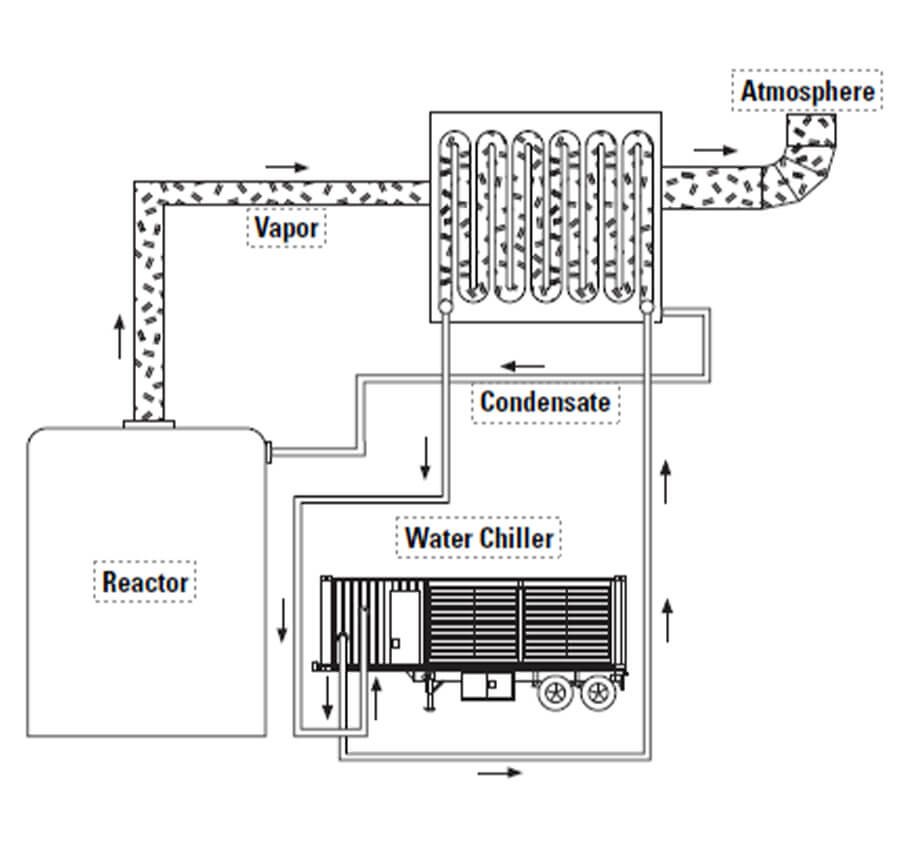

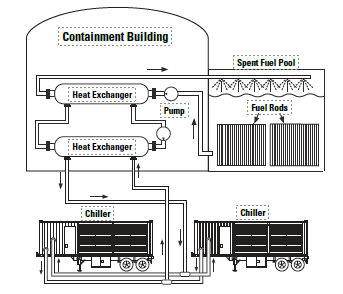

TCRS carries Plate and Frame as well as Shell and Tube Heat Exchangers. Heat Exchangers are a great way to separate our rental equipment from our customer’s process system. This helps keep our equipment clean and free from any hazards that might be part of the customer’s process. We use Heat Exchangers with Chiller rentals as well as Boiler rentals. Heat Exchangers are a necessity when process temperatures are extremely high or low and need to be isolated from the chiller or boiler. The Plate and Frame units come in a variety of sizes and can be adjusted to your specific application, by adding or removing plates to match your specific needs.

Available in sizes ranging from 10-500 tons.

Our products are carefully sourced from the respected plate and frame heat exchanger manufacturers and our experienced team makes sure our recommendations align with your project's goals. These heat exchangers are rental-ready and available for fast delivery and integration within your plant environment. We make it simple to rent a commercial or industrial heat exchanger, as we provide 24/7 services and support to minimize your downtime.

CASE STUDIES

APPLICATIONS & INDUSTRIES WE SERVE

Commercial and industrial heat exchangers are critical components in sustaining a plant's efficiency. We provide rugged heat exchanger rentals to numerous industries to prolong the life of their equipment. Depending on the size and thickness of your rental heat exchanger and the process equipment it integrates with, these units can achieve a variety of performance improvements. Example applications include: Electronics cooling, cooling industrial metals, heating viscous materials, waste heat recovery, food and beverage processing, pharmaceutical and biochemical processing, and more.

CIRCULATION TANKS AND HEAT EXCHANGERS

Process circulation tanks or heat exchangers are used as a means to ensure a supply of cooling fluid with a moderated temperature or flow to a chiller. They may be necessary for applications under the following conditions:

when water temperature from the application to the chiller (entering water temperature) is above 60° F (16° C)

when the water temperature change across the evaporator is less than 5° F (-15° C) or greater than 15° F (-9.4° C)

when cooling fluids or vapors other than water or brine are required

when customer flow requirements are above or below chiller flow rate capabilities

when sudden or dramatic changes in process flow or load exist (common with many batch processes)

Features of Heat Exchangers

Heavy-duty skid frame with full forklift tubes

Four-point leveling pads and lifting eyes

Pre-mounted flow control valve

Single-point overflow, bleed and drain connection

Corrosion protected wetted surfaces

Ground-level Victaulic piping and electrical connections

NEMA 4 control package

Main power input with lockable 40 amp breaker

Pump packages, circulation tanks, heat exchangers

Sometimes a chiller module can be connected directly to the customer’s process and provide the necessary LWT and flow rates. In other cases, supplemental equipment must be added to the chiller. Pump packages can be used to boost fluid flow rates and provide greater head pressures

Circulation tanks may be added when the temperature differential is too great between the required process inlet/outlet temperatures and chiller inlet/outlet.

Heat exchangers may be required if the cooling fluid used by the customer’s process is incompatible with the chiller, or the operating pressures exceed the limits of the equipment.

You’ve got questions. We’ve got answers. Just let us know how we can help by sending us a note or calling us at 877-343-8277.

Industrial Heat Exchangers for Temporary Use.

Tonnage: 500 Material: Stainless Steel Pressure Rating: 150 psi Weight: 5,000 lbs. |

Tonnage: 1,000 Material: Stainless Steel Pressure Rating: 150 psi Weight: 8,000 lbs. |

Tonnage: 1,500 Material: Stainless Steel Pressure Rating: 150 psi Weight: 12,000 lbs. |

The benefits of a heat exchanger rental include avoiding high capital investments and the responsibility of covering insurance, maintenance, and repairs for a unit you own. You can utilize our modern equipment with the resources and support of our experts.

Our rental agreements are also customizable around your project's schedule. We have competitive daily, weekly and monthly rental rates so you have the flexibility and convenience of utilizing your unit only when needed.

Discover the Heat Exchanger Rental Solution for You.

TCRS is committed to providing our customers with the most seamless renting experience possible. We'll ensure the product you're considering is the ideal solution for your application and that you have all the resources for an efficient operation. Contact us to start the process of ordering your heat exchanger rental today.