Supplemental Cooling Tower Water

Typical Cooling Tower Application

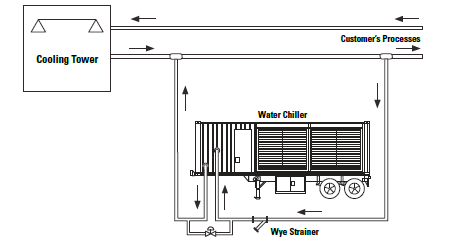

Many industries use cooling towers to supply chilled water to their processes. The capability of these systems depends on ambient temperature and is sometimes limited during seasonal temperature peaks. Rental chillers are the ideal solution to supplement cooling tower capacity and lower water temperature sufficient to support production processes. Rental systems can be piped directly into the cooling tower water circuit, or, as shown in the illustration, divert part or all of the cooling tower water through an additional exchanger.

Rental equipment typically used to provide supplemental capacity to systems using cooling tower water includes the following:

Chiller modules ranging from 50 to 400 tons

Pump modules, circulation tanks, cooling towers, or heat exchanger modules

Piping and fittings

Engineering and supervision services

Installation and maintenance services

On-site operation and training

Typical Customers:

Oil refineries

Utilities

Chemical plants

Paper mills

Rubber or plastic manufacturers

Discovery Questions:

Do you ever have problems with cooling tower water temperatures?

Would lower water temperatures from your cooling towers increase production capacity during the summer months?

Are your cooling towers scheduled for maintenance, repair, or replacement?

Configuration and Installation Issues:

Supplemental cooling applications typically operate in parallel with the customer’s cooling system. Determine the required input and output temperatures and pressures when sizing the chiller. A pump and/or circulation tank may also need to be added to the circuit.

Before tapping directly into a customer’s cooling tower water line, check that the fluid type and quality are compatible with your chiller. If they are not, add an exchanger to the circuit as shown in the example above.

Wye strainers may be required on the chiller inlet line.

A recirculation may be required to prevent inlet temperatures from exceeding 65 degrees Fahrenheit (18.3 degrees Celsius).