Large Motor Cooling

Production processes are sometimes limited during summer months because of overheating of large motors, transformers, motor control centers, and other equipment. This is particularly true when the equipment is in a dirty or dusty environment. An AC unit or chiller/AHU package with ducting to the air intakes of the equipment can reduce power draw, minimize the risk of the equipment tripping off due to overheating and add life to the motor windings.

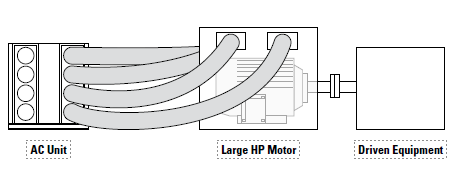

The illustration below shows a typical installation for air cooling large motors.

Air-Cooled Motor Cooling

Large motor and other equipment cooling applications may require any combination of the following rental equipment:

Air-cooled applications typically use air conditioning units or chiller/AHU packages ranging from 30 to 90 tons. Ducting and fittings are usually needed.

Depending upon the application, engineering, supervision, installation, and/or maintenance services might be required.

Water-cooled motors frequently use cooling tower water, so rental opportunities may include your full range of chillers and pump modules. Oil-cooled motors may require either air or fluid temperature control, depending on the type of heat exchanger.

Be sure to identify how the AC or chiller modules will be powered. There may be opportunities for rental power units.

Typical Customers:

Any industrial, mining or commercial operational operation that uses large motors, transformers, or other heat-generating electrical equipment is a potential customer.

Paper and steel mills

Heavy industries

Ore processing facilities

Utilities

Steel mills and foundries

Discovery Questions:

Do you experience any production rate reductions during summer months due to equipment overheating?

Are your large motor’s air-, water-, or oil-cooled? What is the source of cooling air or water?

Do your operators include large electric motors that must operate in dirty or dusty areas? If so, do these motors overheat due to dirty windings?

Configuration and Installation Issues:

Collect the horsepower, ambient temperature, and other nameplate data of all motors the customer wishes to cool. If possible, measure actual motor running temperatures. This will help you determine the correct tonnage of cooling capacity.

Be aware of area electrical classifications.

Special filtration may be required.