Conveyor Cooling

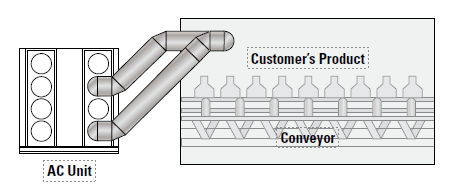

In certain types of manufacturing, products must be cooled as they move on conveyor systems. The faster the products cool, the faster the conveyors can move, which affects production levels. Products can be cooled with a chilled water spray or moved through circulating or blown chilled air, as shown in the diagram below.

Chiller Air Conveyor Cooling

Rental equipment typically used for conveyor cooling applications includes the following:

Air conditioners from 12 to 80 tons

Chiller modules with air handlers ranging from 25 to 525 tons

Ducting, piping, and fittings

Engineering and supervision services

Installation and maintenance services

On-site operation and training

Typical Customers:

Manufacturing plants of all types

Chemical plants

Pharmaceutical companies

Discovery Questions:

Do you use conveyors to cool products during the production process or move products that must remain cool?

Do your production rates slow during the summer months because products do not cool quickly enough?

What systems do you use to provide chilled water or air for product and conveyor cooling? When will these systems be due for maintenance, repair, overhaul, or replacement?

Do you have an emergency backup plan in place to deal with equipment failures and disasters?

Configuration and Installation Issues:

Be sure to consider strainer requirements. For example, conveyor-based hydro cooling of fruit will suck up blossoms and other debris that must be filtered from the cooling water.

Conveyor systems may work in batch mode. Consider these requirements in your flow rate calculations.